Chamfered Side Die . a major factor in key design (eary & reed) involves the size of chamfer on the back side of the die steel (dimension b in fig. Additionally, chamfering is great for creating edges that can join seamlessly. Chamfering is a precision metal fabrication process that involves creating an angled or. a chamfer edge improves visual properties, but it is also a practical option for reasons other than appearance. to address this, designs often incorporate chamfers to smooth or break those sharp edges. the most common way to spec a chamfer is by giving its leg length size and the chamfer angle. This particular type of edge makes it less susceptible to damage and is sturdier than a filet and bevel edge.

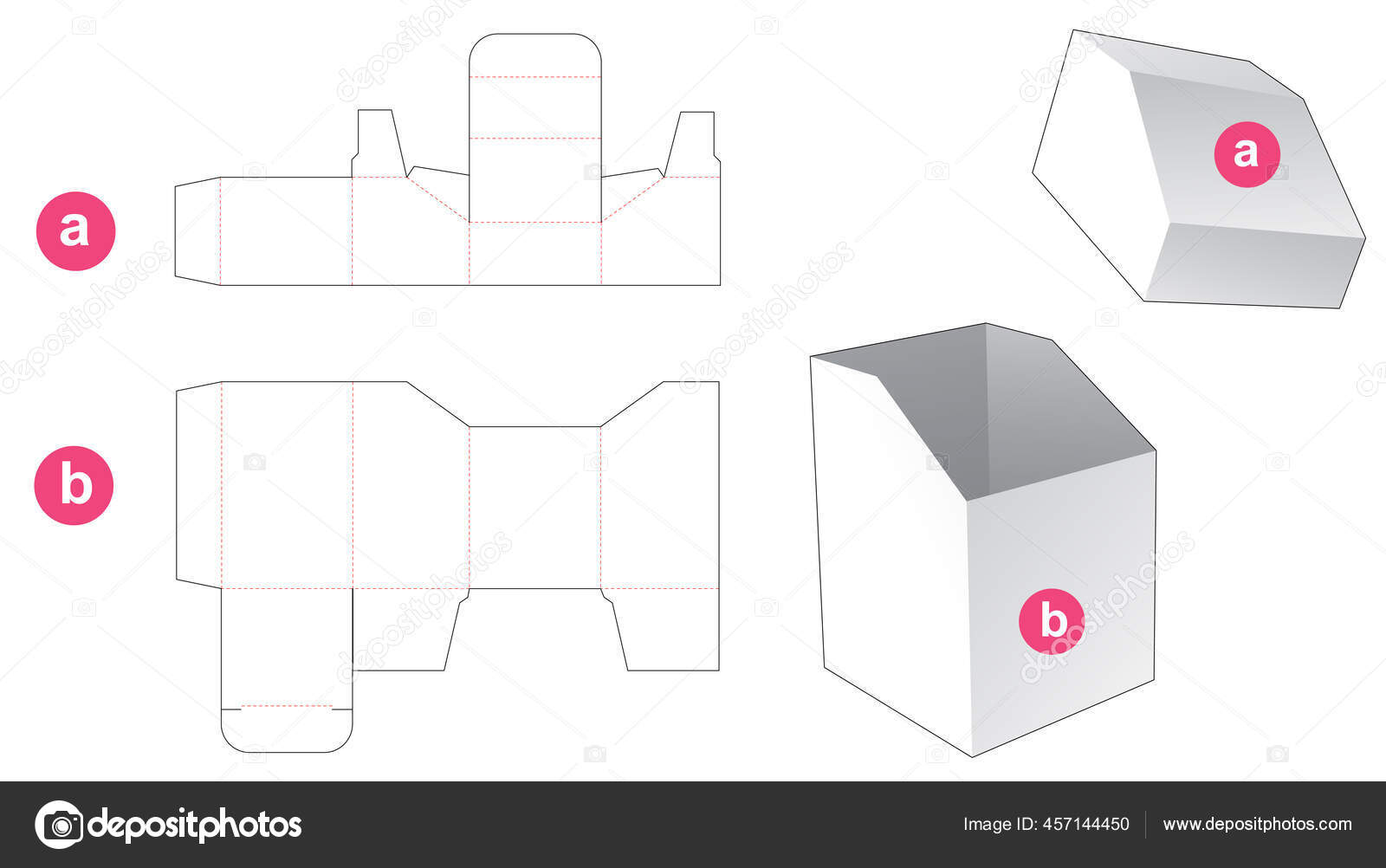

from depositphotos.com

a major factor in key design (eary & reed) involves the size of chamfer on the back side of the die steel (dimension b in fig. This particular type of edge makes it less susceptible to damage and is sturdier than a filet and bevel edge. Chamfering is a precision metal fabrication process that involves creating an angled or. a chamfer edge improves visual properties, but it is also a practical option for reasons other than appearance. to address this, designs often incorporate chamfers to smooth or break those sharp edges. Additionally, chamfering is great for creating edges that can join seamlessly. the most common way to spec a chamfer is by giving its leg length size and the chamfer angle.

Chamfered Box Chamfered Lid Die Cut Template Stock Vector Image by

Chamfered Side Die to address this, designs often incorporate chamfers to smooth or break those sharp edges. This particular type of edge makes it less susceptible to damage and is sturdier than a filet and bevel edge. Additionally, chamfering is great for creating edges that can join seamlessly. to address this, designs often incorporate chamfers to smooth or break those sharp edges. a chamfer edge improves visual properties, but it is also a practical option for reasons other than appearance. the most common way to spec a chamfer is by giving its leg length size and the chamfer angle. a major factor in key design (eary & reed) involves the size of chamfer on the back side of the die steel (dimension b in fig. Chamfering is a precision metal fabrication process that involves creating an angled or.

From www.3qmachining.com

Difference Between a Fillet and Chamfer, Everything You Need To Know Chamfered Side Die the most common way to spec a chamfer is by giving its leg length size and the chamfer angle. a chamfer edge improves visual properties, but it is also a practical option for reasons other than appearance. Additionally, chamfering is great for creating edges that can join seamlessly. a major factor in key design (eary & reed). Chamfered Side Die.

From www.researchgate.net

Chamfered round insert with mesh refinement in AdvantEdge TM Chamfered Side Die a major factor in key design (eary & reed) involves the size of chamfer on the back side of the die steel (dimension b in fig. a chamfer edge improves visual properties, but it is also a practical option for reasons other than appearance. Additionally, chamfering is great for creating edges that can join seamlessly. This particular type. Chamfered Side Die.

From ko.aliexpress.com

10pcs M4 더블 chamfered 솔리드 맞춤 핀 원통형 위치 핀 316 스테인레스 스틸 GB119 샤프트 5mm 20mm Chamfered Side Die a chamfer edge improves visual properties, but it is also a practical option for reasons other than appearance. Chamfering is a precision metal fabrication process that involves creating an angled or. to address this, designs often incorporate chamfers to smooth or break those sharp edges. Additionally, chamfering is great for creating edges that can join seamlessly. This particular. Chamfered Side Die.

From www.qualityquartzsurfaces.co.uk

Chamfered + LED Groove Profile Quality Quartz Surfaces Chamfered Side Die the most common way to spec a chamfer is by giving its leg length size and the chamfer angle. Chamfering is a precision metal fabrication process that involves creating an angled or. a major factor in key design (eary & reed) involves the size of chamfer on the back side of the die steel (dimension b in fig.. Chamfered Side Die.

From projecthub.arduino.cc

Six sided die sketch, part 1 Arduino Project Hub Chamfered Side Die a chamfer edge improves visual properties, but it is also a practical option for reasons other than appearance. Additionally, chamfering is great for creating edges that can join seamlessly. Chamfering is a precision metal fabrication process that involves creating an angled or. a major factor in key design (eary & reed) involves the size of chamfer on the. Chamfered Side Die.

From www.gdandtbasics.com

Chamfer Dimensioning GD&T Basics Chamfered Side Die This particular type of edge makes it less susceptible to damage and is sturdier than a filet and bevel edge. the most common way to spec a chamfer is by giving its leg length size and the chamfer angle. Additionally, chamfering is great for creating edges that can join seamlessly. a major factor in key design (eary &. Chamfered Side Die.

From www.abbydirecttimber.co.uk

75mm Chamfered Architrave (3″) Abby Direct Timber Supplies Chamfered Side Die a major factor in key design (eary & reed) involves the size of chamfer on the back side of the die steel (dimension b in fig. This particular type of edge makes it less susceptible to damage and is sturdier than a filet and bevel edge. to address this, designs often incorporate chamfers to smooth or break those. Chamfered Side Die.

From www.youtube.com

Chamfering the Edge ToolsToday YouTube Chamfered Side Die to address this, designs often incorporate chamfers to smooth or break those sharp edges. the most common way to spec a chamfer is by giving its leg length size and the chamfer angle. a major factor in key design (eary & reed) involves the size of chamfer on the back side of the die steel (dimension b. Chamfered Side Die.

From www.researchgate.net

The performance of the stopping fluid at the neck outer edge of the Chamfered Side Die a chamfer edge improves visual properties, but it is also a practical option for reasons other than appearance. Chamfering is a precision metal fabrication process that involves creating an angled or. Additionally, chamfering is great for creating edges that can join seamlessly. This particular type of edge makes it less susceptible to damage and is sturdier than a filet. Chamfered Side Die.

From whoward.co.uk

Chamfered & Single V Grooved W Howard Group MDF Profiling Chamfered Side Die This particular type of edge makes it less susceptible to damage and is sturdier than a filet and bevel edge. a chamfer edge improves visual properties, but it is also a practical option for reasons other than appearance. Additionally, chamfering is great for creating edges that can join seamlessly. the most common way to spec a chamfer is. Chamfered Side Die.

From www.autodesk.com

How to chamfer two edges in one pass in Fusion 360 Manufacture Chamfered Side Die to address this, designs often incorporate chamfers to smooth or break those sharp edges. a major factor in key design (eary & reed) involves the size of chamfer on the back side of the die steel (dimension b in fig. This particular type of edge makes it less susceptible to damage and is sturdier than a filet and. Chamfered Side Die.

From depositphotos.com

Chamfered Box Chamfered Lid Die Cut Template Stock Vector Image by Chamfered Side Die Additionally, chamfering is great for creating edges that can join seamlessly. the most common way to spec a chamfer is by giving its leg length size and the chamfer angle. a major factor in key design (eary & reed) involves the size of chamfer on the back side of the die steel (dimension b in fig. This particular. Chamfered Side Die.

From www.youtube.com

Tapping & Chamfering 3/4" Waterjet Holes Offline (From Hand Tapping to Chamfered Side Die Additionally, chamfering is great for creating edges that can join seamlessly. a chamfer edge improves visual properties, but it is also a practical option for reasons other than appearance. a major factor in key design (eary & reed) involves the size of chamfer on the back side of the die steel (dimension b in fig. This particular type. Chamfered Side Die.

From www.finepowertools.com

Bevel vs Chamfer Difference Between the Edges Demystified. Chamfered Side Die Additionally, chamfering is great for creating edges that can join seamlessly. This particular type of edge makes it less susceptible to damage and is sturdier than a filet and bevel edge. a chamfer edge improves visual properties, but it is also a practical option for reasons other than appearance. to address this, designs often incorporate chamfers to smooth. Chamfered Side Die.

From www.arrmaforum.com

Chamfered wrond side ARRMA RC Forum Chamfered Side Die a chamfer edge improves visual properties, but it is also a practical option for reasons other than appearance. a major factor in key design (eary & reed) involves the size of chamfer on the back side of the die steel (dimension b in fig. Additionally, chamfering is great for creating edges that can join seamlessly. Chamfering is a. Chamfered Side Die.

From www.vectorstock.com

Two chamfered drawers and chamfered cover die cut Vector Image Chamfered Side Die to address this, designs often incorporate chamfers to smooth or break those sharp edges. This particular type of edge makes it less susceptible to damage and is sturdier than a filet and bevel edge. Chamfering is a precision metal fabrication process that involves creating an angled or. the most common way to spec a chamfer is by giving. Chamfered Side Die.

From www.youtube.com

Chamfering metal chamfer metal YouTube Chamfered Side Die a major factor in key design (eary & reed) involves the size of chamfer on the back side of the die steel (dimension b in fig. a chamfer edge improves visual properties, but it is also a practical option for reasons other than appearance. This particular type of edge makes it less susceptible to damage and is sturdier. Chamfered Side Die.

From www.hartmetalluk.com

Fixed length, chamfered one end Hartmetall UK Chamfered Side Die Chamfering is a precision metal fabrication process that involves creating an angled or. a chamfer edge improves visual properties, but it is also a practical option for reasons other than appearance. the most common way to spec a chamfer is by giving its leg length size and the chamfer angle. This particular type of edge makes it less. Chamfered Side Die.